The Ultimate Guide to Glass Melting Point: From Chemistry to Manufacturing

The Ultimate Guide to Glass Melting Point: From Chemistry to Manufacturing

Understanding Glass Melting Points

The melting point of glass pertains to the specific temperature range at which solid glass transforms into a liquid state, typically falling between 1,400 and 1,600 degrees Celsius, depending on the composition. Unlike crystalline substances that possess distinct melting points, glass is classified as an amorphous solid, exhibiting a gradual softening process rather than a sudden melting transition. This characteristic is crucial for both scientific research and commercial applications, making it essential to grasp the nuances of glass softening behavior.

The melting temperature of glass is influenced by a variety of factors, primarily its chemical composition. Different types of glass — such as soda-lime, borosilicate, fused silica, aluminosilicate, and lead glass — exhibit distinct melting points due to their unique formulations.

1.Chemical Composition Overview

Soda Lime Glass

As the most widely used glass type, soda-lime glass has a melting range of 1500°C to 1600°C. Its blend of silica, lime, and soda contributes to this relatively low melting point, making it suitable for manufacturing a diverse array of household products.

Borosilicate Glass

Renowned for its superior thermal resistance, borosilicate glass melts at higher temperatures, specifically between 1640°C and 1710°C. Its low thermal expansion coefficient renders it ideal for applications requiring high-temperature stability, such as laboratory instruments and cooking ware.

Fused Silica Glass

Also referred to as quartz glass, fused silica exhibits a melting point of approximately 1700°C. This type of glass is characterized by its high purity and thermal stability, making it an excellent option for optical devices and precision scientific equipment, including microscopes.

Aluminosilicate Glass

With a melting point exceeding 2000°C, aluminosilicate glass is recognized for its exceptional thermal shock resistance and mechanical durability. These attributes position it as a preferred material for high-performance applications, including aerospace components and specialized windows.

Lead Glass

Melting within the range of 800°C to 900°C, lead glass incorporates lead as a key ingredient, resulting in a malleable product suitable for crafting elaborate glassware and decorative pieces.

2. Impurities and Additives

The introduction of even trace amounts of additives such as iron, alumina, or magnesium can significantly affect the melting point of glass. For example, incorporating sodium carbonate can reduce the melting temperature, facilitating the glassblowing process.

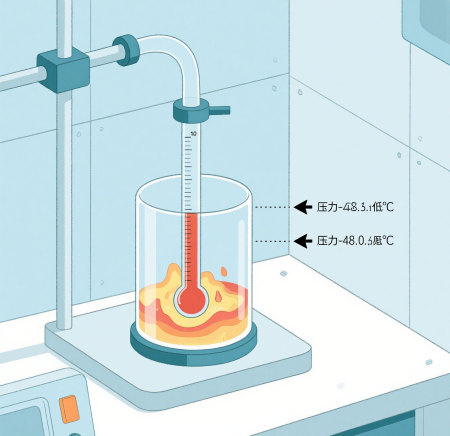

3. Pressure and Atmosphere

The melting point is influenced by pressure, with increased pressure typically resulting in higher melting temperatures. Additionally, managing atmospheric conditions — such as an environment rich in oxygen or nitrogen — can considerably modify melting characteristics in manufacturing settings.

4. Heating Rate and Duration

The rate at which glass is heated plays a crucial role in melting efficiency. Rapid heating may lead to inconsistent melting, while a slower heating process promotes a more uniform temperature distribution, ultimately affecting the overall properties of the material.

5. Thermal History

The previous thermal treatments of glass can impact its current melting point. Repeated heating cycles may lower the softening temperature due to structural transformations within the material, thereby altering both its softening and melting points.

6. Crystallization

If crystallization occurs during the heating phase, the melting point will increase, as crystalline structures possess higher melting temperatures compared to amorphous glass.

Distinction Between Glass Melting Point and Transition Temperature

A common area of misunderstanding in the field of glass materials lies in the differentiation between melting point and transition temperature (Tg). Melting point denotes the transformation of a solid into a viscous liquid, whereas Tg indicates the point at which a solid transitions to a rubbery-soft state. It is important to note that Tg is typically lower than the melting point, particularly in processes such as glass annealing and tempering. A comprehensive understanding of these concepts is essential for professionals and researchers engaged in glass-related work.

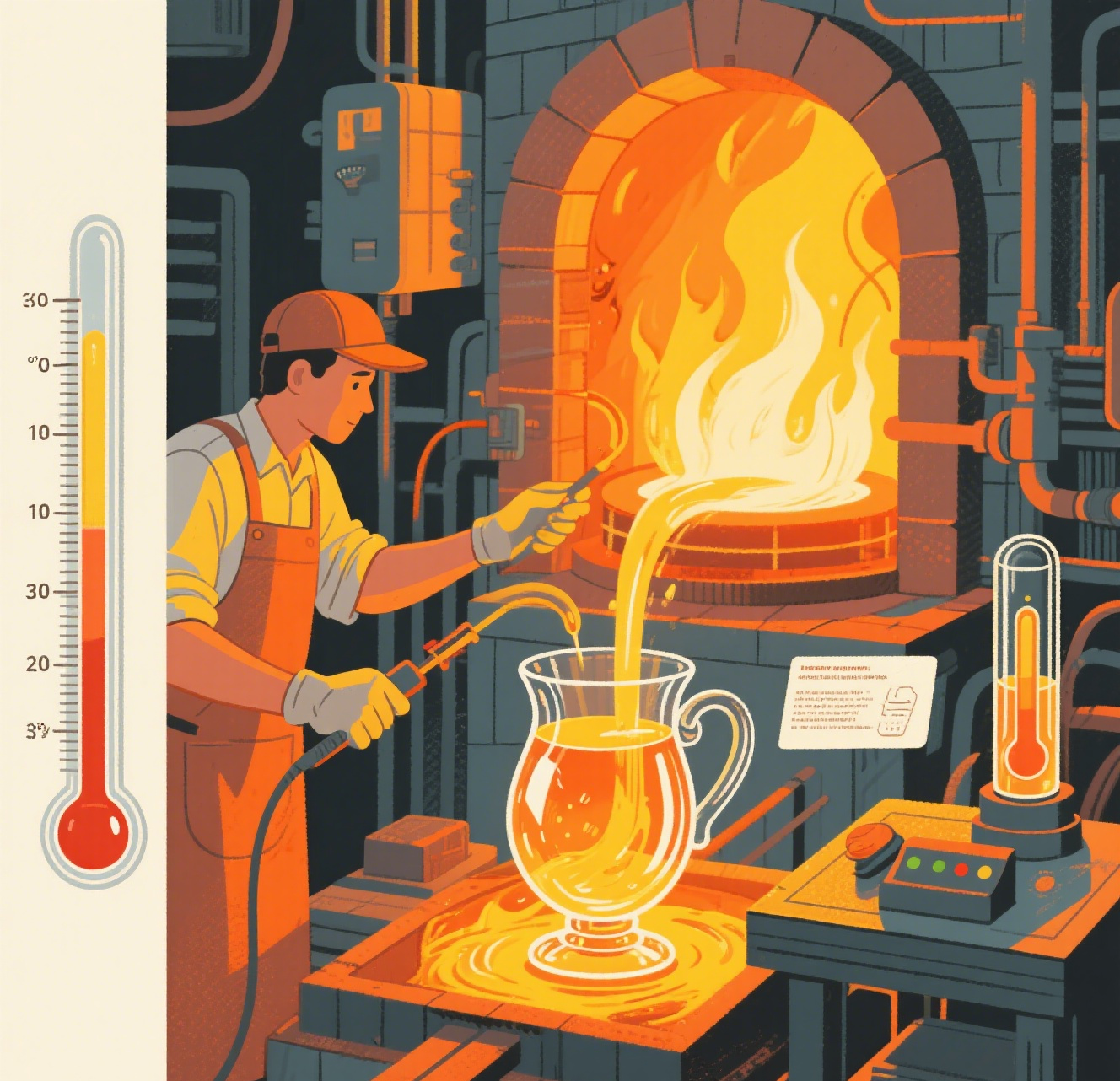

The Significance of Glass Melting Temperature in Production

The melting temperature of glass is a crucial factor in the manufacturing of high-quality glass products, including containers and windows. Precise management of this temperature during production is essential to achieve consistent quality across various applications, from delicate jewelry to sturdy windows. Techniques such as glassblowing, pressing, and drawing necessitate specific temperature controls to yield the desired results. For instance:

- In glassblowing, it is important to maintain the right viscosity for effective shaping.

- Pressing demands elevated temperatures to ensure accurate molding of the final product.

- Drawing, particularly in fiber optics applications, requires meticulous temperature and environmental regulation to produce thin structures with uniform thickness.