Understanding Glass Bottle Frosting: Answers to Your Questions for a High-Quality Result

Understanding Glass Bottle Frosting: Answers to Your Questions for a High-Quality Result

In today's competitive market, how you showcase your products is nearly as crucial as the products themselves. Packaging serves as the initial point of contact and visual engagement for consumers with your brand. For beverages like spirits, wines, and other drinks, the bottle acts as a quiet representative of your brand. One of the most sophisticated methods to enhance your drink's attractiveness is through glass frosting. This technique elevates a standard glass bottle into a refined vessel that embodies luxury and top-notch quality.

What Exactly is Glass Bottle Frosting?

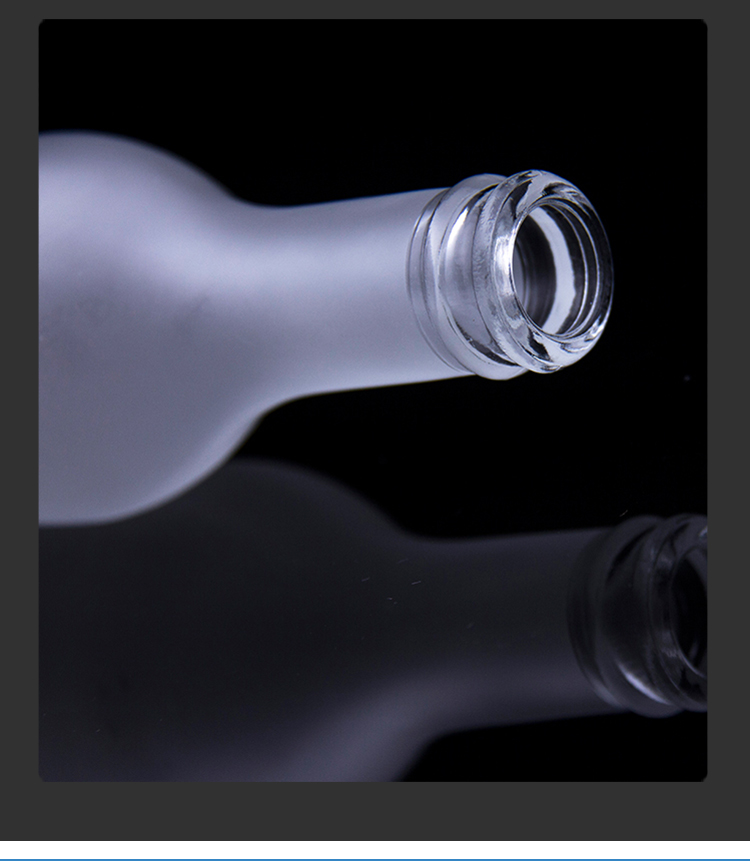

Frosting a glass bottle involves changing its surface to create a matte finish that appears translucent, often characterized by an "icy" or "velvety" texture. Unlike clear glass that showcases its contents fully or opaque glass that completely conceals them, frosted glass serves as a delicate barrier, subtly revealing what's inside while adding an element of intrigue and sophistication.

The characteristic isn't exclusive to the glass itself; rather, it's an additional layer applied to standard glass bottles. This coating produces a soft, diffused glow and offers a unique tactile sensation that enhances consumer interaction with the product. The appearance of frosted glass elevates a bottle's aesthetic, making it a popular choice for brands aiming to stand out in the market.

How is Glass Bottle Frosting Achieved? Unveiling the Techniques

There are numerous techniques to achieve a frosted appearance on glass bottles, each possessing unique features and specific requirements for different applications. Familiarity with these methods will enable you to choose the most suitable option that aligns with your business's needs and preferences.

1. Acid Etching

Acid etching is a widely recognized technique for achieving a frosted effect on glass. This process entails the use of acidic agents—traditionally hydrofluoric acid, though other alternatives are becoming more popular—applied to the glass surface. The acid subtly erodes the outer layer of the glass, resulting in a fine, smooth, and durable frosted finish.

- High-Quality Finish: Produces a smooth, uniform, and premium glossy finish. This is one of the best frosting techniques.

- The durability is Frosted effects last forever, won't peel off, scratch or fade away because they are a part the glass layer.

- Design complexity: Ideal for creating intricate designs and crisp lines. It can be used to create full frosting or selective frosting to create designs or artistic elements.

- Beware: This process requires specialized knowledge and facilities due to its chemical composition.

2. Sandblasting (Abrasive Blasting)

Sandblasting, commonly known as abrasive blasting, is a technique that employs mechanical energy to launch tiny abrasive materials—such as aluminum oxide, sand, or silicon carbide—at high velocities onto a glass surface. This action causes physical alterations to the glass, resulting in a pitted texture that resembles frost.

- Finish High-quality: Can produce various texture, from a soft frost, to a darker and more opaque appearance, dependent on the material used as well as the amount of pressure applied and duration.

- durability: This effect of frosting is long-lasting and extremely durable.

- Design Complexity Excellent for general frosting. It can also be utilized using stencils to create simple patterns or for larger areas of frosting. The technique may not provide the same degree of high-quality detail that acid engraving.

- Beware of: The texture can occasionally feel rougher than acid-etched glass.

3. Spray Coatings (Frosting Sprays/Paints)

This method entails applying a layer of coating or paint onto the glass, which then dries to produce an appearance akin to frosted glass. Typically, these coatings are made from polymers.

- High-Quality Finish: Can create a visually pleasing frosted finish and can achieve a variety of frosting colors.

- Durability: The method is typically the most fragile method. After a certain period, the coating can chip, peel or scratch, especially if it is repeatedly exposed to moisture or handled. It is not common in high-end durable or returnable packaging, such as high-end spirits bottles.

- Complexity in Design: Can be used to apply different colors and can be economical when it comes to specific products or applications.

- The pros: It offers a frosted appearance, but it does not provide the same tactile or durability experience as etching and Sandblasting. If you want a brand to have a premium appearance and also maintain enduring quality, then etched or sandblasted options are the best choice.

The Alluring Benefits of Choosing Frosted Glass Bottles

This method entails applying a layer of coating or paint onto the glass, which then dries to produce an appearance akin to frosted glass. Typically, these coatings are made from polymers.

- Enhance Aesthetic Appearance and Luxury Style: This may be the most immediate benefit. Frosted glasses immediately convey elegance, class and elegance. This makes the product look more attractive on shelves and signals to customers that it is a high-quality product. It is especially useful for high-end Whiskey Bottles, exquisite Vodka bottles, and unique Gin Bottles.

- A Better Tactile Feel The smooth or silky exterior of a bottle coated with a frosted finish gives an enjoyable and distinct experience. It can create a stronger connection between the user of the product and the item. This makes the experience more memorable.

- Subtle product revelation Frosted glasses are a great way to reveal the color and clarity of a drink without revealing too much. This is especially true for spirits like Whiskey Bottles and sparkling liquors.

- Higher Perceived Worth Due to its elegant design and packaging, customers often associate frosted-glass packaging with higher-value merchandise. This perception can boost the reputation of the brand and support the price.

- Flexibility of Design: Frosting doesn't have to be all or nothing. This technique can be used to cover the entire bottle with gradients or in intricate logos and designs. This technique allows for unique branding and can be used in conjunction with other decoration methods such as screen printing or embossing. Imagine adding a transparent window to an Brandy Bottle, so that the vibrant color can be seen.

- Light Diffusion Although it is not the primary method of UV protection (other methods are more effective), the diffused nature of glass with a frosted finish can shield delicate items from harsh light. This can be beneficial for certain wines or drinks.

Comparing Frosting Techniques

Feature | Acid Etching | Sandblasting | Spray Coatings (Frosting Paints) |

| Finish Quality | The surface is smooth and satin. top-quality, constant | Textured, it can range from mild to deep frost | Excellent visual. Can be colorized |

| Durability | Long-lasting, strong resistance against scratches | Long-lasting, strong resistance | Lower may scratch, peel or chip |

| Design Detail | Excellent for intricate & fine designs | Great for general frost and more simple designs | Flexible, based on the application technique |

| Tactile Feel | Smooth, velvety | A little textured, but not noticeable. | There are many variations, but it is usually silky but can feel as if you’ve got a coat |

| Typical Use | Premium wines, premium spirits Luxury cosmetics, premium spirits | Beverage bottles, decorative glass items | Projects for crafts, temporary costs |

Make Your Brand Stand Out with High-Quality Frosted Finish

Frosting on glass bottles presents an excellent chance to set your products apart, enhance sophistication, and elevate the customer experience. The refined look and unique texture of frosted glass can elevate your packaging from a mere vessel to a striking representation of your brand.

If you're keen on discovering how glass bottle frosting can boost your visibility and attract potential customers, the IDEA BOTTLES team is ready to help. Reach out to us today to brainstorm custom-frosted glass bottle concepts, and we'll support you in crafting a standout bottle that will establish your brand globally.